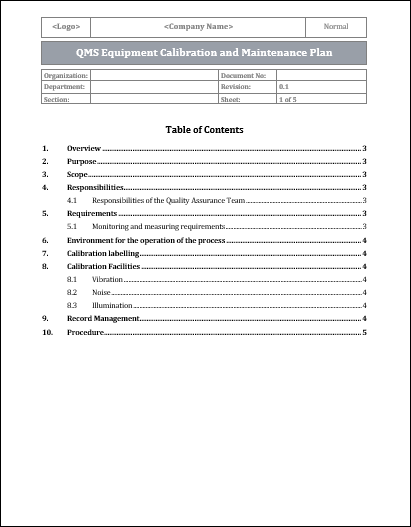

ISO 9001 Equipment Calibration And Maintenance Plan Template

ISO 9001 is a recognized quality management standard. The Equipment Calibration and Maintenance Plan Template helps organizations meet this standard by providing a structured approach for managing equipment calibration and maintenance. The template outlines steps to identify equipment, establish calibration intervals, and document calibration records. Using this template can improve process efficiency, reduce non-conformities, and demonstrate a commitment to quality. It is a valuable tool for meeting ISO 9001 requirements.

Understanding The Importance of Equipment Calibration and Maintenance Plan

- Accurate measurements: Equipment calibration ensures that measurements obtained from the equipment are accurate and reliable. This is crucial in various industries such as healthcare, manufacturing, and environmental monitoring, where incorrect measurements can lead to costly errors or even pose a danger to people's health and safety.

- Compliance with regulations: Many industries are subject to regulations that require regular equipment calibration. This ensures that organizations meet the required industry standards and legal obligations. Non-compliance can result in fines, legal disputes, or loss of accreditation or certification.

- Increased reliability and efficiency: Regular calibration and maintenance of equipment help identify any potential issues or malfunctions early on, allowing for timely repairs or replacements. This reduces the risk of costly breakdowns or production delays, ensuring smooth operations and increased efficiency.

- Extended equipment lifespan: Proper calibration and maintenance can help prolong the lifespan of equipment. Regular checks can prevent minor problems from developing into major faults, increasing the longevity of the equipment and reducing the need for frequent replacements.

- Improved quality control: Calibrated equipment helps maintain consistent quality control processes. This is essential in industries such as food production and pharmaceuticals, where precise measurements and adherence to quality standards are vital for product safety and customer satisfaction.

- Enhanced customer trust: When organizations can demonstrate that their equipment is regularly calibrated and maintained, it generates trust and confidence among customers and stakeholders. This can result in increased customer loyalty and a positive reputation for the organization.

- Cost savings: By ensuring accurate measurements and preventing equipment failures, regular calibration and maintenance can help reduce costs associated with rework, product recalls, or legal disputes caused by faulty measurements. It also minimizes the need for emergency repairs or replacements.

- Safety assurance: Equipment calibration is crucial for ensuring the safety of both employees and the public. Incorrectly calibrated equipment can pose serious risks, such as inaccurate medical diagnoses or safety hazards in industrial settings. Regular maintenance plans help identify and address these risks promptly.

- Data integrity: Calibrated equipment provides reliable data, ensuring the integrity of research studies, scientific experiments, or data-driven decision-making processes. This is especially important in industries such as pharmaceuticals, environmental monitoring, or forensic investigations.

- Compliance with quality management systems: Many quality management systems, such as ISO 9001, require organizations to have a robust equipment calibration and maintenance plan in place. Following such standards not only ensures compliance but also promotes continuous improvement and customer satisfaction.

Key Components of ISO 9001 Equipment Calibration And Maintenance Plan

This refers to the main elements that should be included in the plan to ensure compliance with ISO 9001 standards for equipment calibration and maintenance. These components may include a list of equipment to be calibrated, frequency of calibration, methods and procedures to be followed, personnel responsible for the calibration, and documentation requirements.

- Description of Change: This refers to any changes or modifications made to the equipment calibration and maintenance plan. It is important to document and describe any updates or adjustments made to the plan to ensure a clear understanding of the changes and to maintain an accurate record of the plan over time.

- Retention Period: This refers to the length of time that records of equipment calibration and maintenance activities should be kept. ISO 9001 typically requires organizations to retain these records for a defined period to demonstrate compliance with the standard and to track the history and performance of the equipment. The retention period may vary depending on industry regulations and specific organizational requirements.

- Calibration Labelling: This refers to the practice of labeling calibrated equipment to indicate that it has been verified and meets the required standards. Each calibrated equipment should be appropriately labeled with essential information, such as the calibration date, the due date for the next calibration, and the name of the person responsible for calibration. Proper labeling helps to ensure that equipment remains in calibration and can be easily identified and tracked.

- Approval Remarks: This refers to comments or remarks made during the approval process of the equipment calibration and maintenance plan. It may include any notes or feedback provided by reviewers or auditors who assessed the plan for compliance with ISO 9001 requirements. Approval remarks are valuable for ensuring that the plan meets the necessary standards and can help identify areas that may need improvement or further attention.

The Benefits of Implementing an ISO 9001 Equipment Calibration and Maintenance Plan

- Improved equipment reliability: Implementing ISO 9001 equipment calibration and maintenance plan ensures that equipment is regularly checked and maintained, which reduces the likelihood of unexpected breakdowns and ensures reliable performance. This helps to minimize production downtime and maintain consistent product quality.

- Enhanced product quality: Regular equipment calibration ensures that measurements and readings taken by the equipment are accurate. This is particularly important in industries where precision and accuracy are crucial, such as pharmaceuticals, laboratories, and manufacturing. Accurate measurements lead to better quality control and reduced product defects.

- Compliance with regulatory requirements: Many industries have strict regulatory requirements for equipment calibration and maintenance. Implementing an ISO 9001 equipment calibration and maintenance plan helps to ensure compliance with these regulations, reducing the risk of penalties, fines, and legal issues.

- Long equipment lifespan: Regular calibration and maintenance help to prolong the lifespan of equipment. By identifying and addressing issues early on, potential breakdowns and costly repairs can be avoided. This reduces the need for premature replacement of equipment, saving costs in the long run.

- Increased customer satisfaction: Implementing an ISO 9001 equipment calibration and maintenance plan demonstrates your commitment to providing high-quality products or services to your customers. This can enhance customer satisfaction and confidence in your organization, leading to customer loyalty and repeat business.

- Efficient resource utilization: A well-implemented equipment calibration and maintenance plan ensures that resources, such as manpower, time, and materials, are utilized efficiently. Scheduled maintenance activities can be planned and coordinated effectively, minimizing equipment downtime and optimizing productivity.

- Improved risk management: Regular equipment calibration and maintenance allow for early detection of potential issues or deviations. By addressing these issues promptly, the risk of equipment failures, production delays, and safety hazards can be minimized. This helps to protect your business from unforeseen risks and ensures continuity of operations.

- Continuous improvement: Implementing an ISO 9001 equipment calibration and maintenance plan provides opportunities for continuous improvement. By monitoring equipment performance and analyzing data obtained from calibration and maintenance activities, you can identify areas for improvement and implement corrective actions to enhance efficiency and effectiveness.

In conclusion, implementing an ISO 9001 equipment calibration and maintenance plan offers numerous benefits such as improved equipment reliability, enhanced product quality, compliance with regulatory requirements, increased customer satisfaction, efficient resource utilization, improved risk management, and opportunities for continuous improvement.

Conclusion

A strong Equipment Calibration and Maintenance Plan is crucial for accuracy and reliability of equipment. Compliance with ISO 9001 standards is maintained through regular calibration and maintenance. This plan minimizes errors, prevents malfunctions, and improves product or service quality. The plan should include a schedule, detailed procedures, and documentation.