ISO 45001 Approved Supplier List Template

Introduction

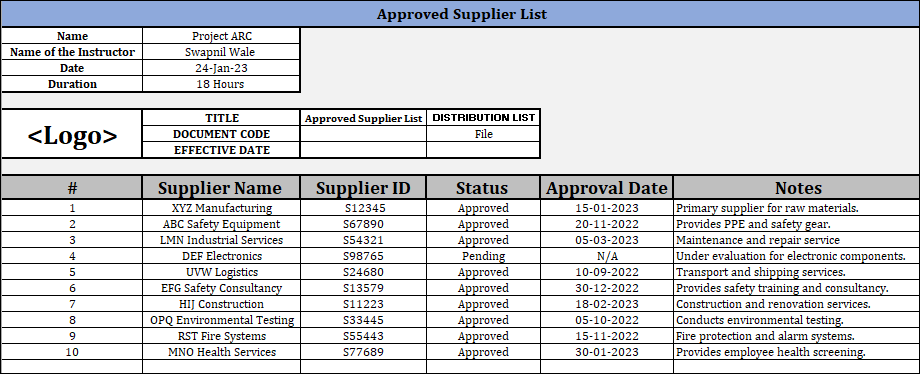

Creating and maintaining an approved supplier list is crucial to ISO 45001 compliance. Many organizations use a template specifically designed for ISO 45001 to streamline this process and ensure consistency. This template helps standardize the approval criteria and ensures that all relevant information is documented. By implementing an approved supplier list concerning ISO 45001, organizations can enhance their supply chain management practices and mitigate risks associated with non-compliant suppliers. This article will explore the benefits of using a template for your approved supplier list and guide you on effectively implementing this process within your organization.

Overview Of ISO 45001 And Its Relevance To Supplier Management

ISO 45001 is an international standard that provides occupational health and safety management systems guidelines. It helps organizations establish and maintain processes and practices to prevent work-related injuries, illnesses, and accidents. ISO 45001 is relevant to supplier management as it emphasizes the importance of managing the health and safety risks associated with suppliers' products and services.

By incorporating ISO 45001 requirements into supplier management processes, organizations can ensure that their suppliers are committed to providing safe and healthy working conditions for their employees. This helps prevent potential harm to workers involved in the supply chain and promotes a safety culture throughout the organization's operations. Compliance with ISO 45001 can also be a competitive advantage, demonstrating an organization's commitment to upholding high occupational health and safety standards.

The Significance Of An Approved Supplier List In ISO 45001 Certification

1. Ensures Compliance With ISO 45001 Standards: An Approved Supplier List (ASL) is an essential component of an ISO 45001 certification as it helps ensure that only suppliers who meet the required standards are used.

2. Mitigates Risks: Organizations with an ASL can reduce the potential risks of using unreliable or unsafe suppliers. This helps protect the health and safety of employees and the organization's reputation.

3. Promotes Consistency In Supplier Selection: An ASL ensures suppliers are selected based on consistent criteria, such as quality, safety, and compliance with relevant regulations. This promotes fair competition among suppliers and helps organizations make informed decisions.

4. Streamlines Purchasing Processes: Having an ASL simplifies the purchasing process by providing a pre-approved list of suppliers vetted for compliance with ISO 45001 requirements. This saves time and effort in searching for and evaluating suppliers.

5. Ensures Traceability And Accountability: An ASL enables organizations to maintain proper documentation and traceability of their suppliers. This helps demonstrate accountability and provides evidence of due diligence in supplier selection and management.

6. Encourages Continuous Improvement: By consistently evaluating and monitoring suppliers' performance against ISO 45001 criteria, organizations can identify areas for improvement and work collaboratively with suppliers to enhance their health and safety practices.

7. Enhances Stakeholder Confidence: Demonstrating a robust ASL to stakeholders, such as customers, regulatory agencies, and investors, enhances their confidence in the organization's commitment to health and safety and compliance with ISO 45001 requirements.

8. Facilitates Supplier Relationship Management: An ASL enables organizations to establish clear supplier expectations and requirements, fostering a stronger and more effective working relationship. This can lead to improved communication, collaboration, and overall supplier performance.

9. Supports Audits And Assessments: During ISO 45001 audits, having a well-maintained ASL provides auditors with essential information about the organization's supplier management practices. It helps demonstrate compliance with the standard's requirements and facilitates a smoother audit process.

10. Promotes A Culture Of Safety: By working with suppliers who meet ISO 45001 standards, organizations create a safety culture throughout the supply chain. This can lead to higher employee morale, improved health and safety outcomes, and a safer work environment.

Best Practices For Managing And Updating Your Approved Supplier List

1. Define Clear Criteria: Establish a set of criteria suppliers must meet to be considered for approval. This may include product quality, reliability, financial stability, and adherence to regulatory standards.

2. Conduct Initial Supplier Evaluations: Evaluate potential suppliers based on the criteria. This may involve reviewing their credentials, conducting site visits, assessing their production processes, and analyzing their previous business performance.

3. Create A Comprehensive Approved Supplier List (ASL): Once suppliers have been evaluated and approved, compile a detailed ASL that includes their contact information, products or services they offer, and any specific notes or qualifications.

4. Regularly Review And Update The ASL: Set a schedule for periodic reviews of your ASL to ensure it remains current. This may include reassessing existing suppliers and adding or removing suppliers based on their performance or changes in your business needs.

5. Communicate Changes To Relevant Stakeholders: Notify all relevant departments or employees of any updates or changes to the ASL. This will ensure everyone knows the approved suppliers and can make informed decisions when selecting suppliers for various projects or procurement needs.

6. Implement A Review And Evaluation Process: Establish a method to evaluate supplier performance continuously. This may involve gathering feedback from internal stakeholders, monitoring product or service quality, measuring delivery timeliness, and assessing overall customer satisfaction.

7. Address Non-conformances Or Issues Promptly: If any non-conformance or quality issues arise with an approved supplier, follow appropriate corrective actions and document the steps taken to resolve the issues. This can include conducting root cause analysis, implementing preventive measures, and monitoring supplier performance to ensure compliance with required standards.

8. Foster Open Communication: Maintain open lines of communication with approved suppliers to discuss any concerns, changes in requirements, or improvements that may be necessary. Regularly engage in dialogues to strengthen the partnership and resolve any challenges that may arise.

9. Seek End-user Feedback: Gather feedback from employees or end-users who interact with approved suppliers. This feedback can provide valuable insights into product/service quality, customer service, and other subjective factors that may impact supplier performance.

10. Continually Improve Your ASL Process: Review your supplier management process for opportunities to enhance efficiency and effectiveness. This may involve leveraging technology or software solutions to streamline supplier evaluation and communication or adopting industry best practices to stay updated with current trends and standards.

Conclusion

In conclusion, having an Approved Supplier List by ISO 45001 is crucial for ensuring the safety and quality of products and services in any organization. This template provides a comprehensive framework for creating and maintaining a list, helping businesses streamline supplier evaluation and selection processes. By using this template, organizations can demonstrate their commitment to meeting the highest occupational health and safety standards and enhance their overall risk management practices. Download the Approved Supplier List concerning the ISO 45001 Template to optimize your supplier management processes and enhance your company's performance.