Understanding Non-Conformance: Definition and Impact

In any organizational setting, maintaining high standards of quality and efficiency is paramount to success. However, even in the most well-run operations, deviations from established standards and procedures can occur. These deviations are often referred to as "non-conformance." In this comprehensive guide, we will explore the meaning of non-conformance, its various types, causes, consequences, and most importantly, how organizations can effectively manage and prevent non-conformance issues.

Defining Non-Conformance

Non-Conformance can be broadly defined as any deviation, departure, or failure to meet established standards, specifications, regulations, or procedures within an organization. It can manifest in various forms, such as product defects, process inefficiencies, documentation errors, or even violations of regulatory requirements. Non-conformance essentially indicates that something within the organization is not working as intended or expected.

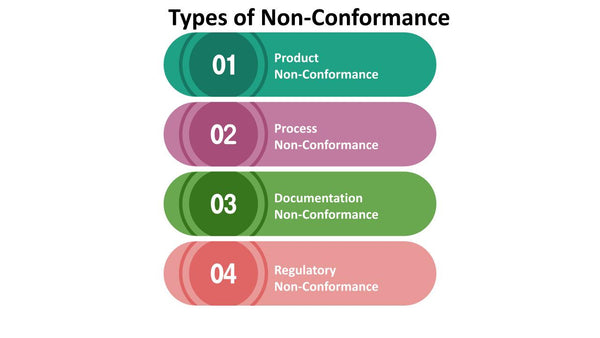

Types Of Non-Conformance

- Product Non-Conformance: This type of non-conformance occurs when a product, whether it's a physical item or a service, does not meet the quality standards, specifications, or requirements set by the organization. This can result in defects, malfunctions, or customer dissatisfaction.

- Process Non-Conformance: Process non-conformance involves deviations or inefficiencies in the way tasks, workflows, or processes are executed within an organization. This can lead to delays, errors, and increased operational costs.

- Documentation Non-Conformance: Documentation is a critical aspect of many industries, especially in regulated sectors like healthcare and manufacturing. Documentation non-conformance refers to errors or inaccuracies in records, reports, or documentation that can have legal, safety, or compliance implications.

- Regulatory Non-Conformance: In highly regulated industries, organizations must adhere to specific laws, regulations, and standards. Regulatory it occurs when an organization fails to comply with these requirements, potentially leading to legal penalties or other serious consequences.

Causes Of Non-Conformance

It can stem from various sources, and understanding these root causes is essential for effective prevention and management. Some common causes include:

- Human Error: Mistakes made by employees, whether due to lack of training, oversight, or fatigue, can result in issues.

- Inadequate Training: Insufficient training or a lack of clear procedures can lead to employees not understanding or following the correct processes.

- Equipment Malfunctions: Mechanical failures or equipment malfunctions can lead to non-conformance in manufacturing and production settings.

- Poor Communication: Miscommunication or lack of communication between team members or departments can result in deviations from established standards.

- Inadequate Resources: Insufficient resources, such as time, budget, or personnel, can hinder the ability to meet quality standards and requirements.

- Supplier Issues: Non-conformance can also arise from problems with suppliers, such as receiving subpar materials or components.

Consequences Of Non-Conformance

The consequences of non-conformance can be significant and wide-ranging, impacting both the organization and its stakeholders. Some of the potential consequences include:

- Financial Loss: Non-conformance can lead to increased costs, such as rework, warranty claims, or fines for regulatory violations.

- Reputation Damage: Poor quality products or services resulting from non-conformance can tarnish an organization's reputation and erode customer trust.

- Legal Consequences: Regulatory non-conformance can result in legal actions, fines, or penalties.

- Reduced Productivity: Process non-conformance can lead to delays, inefficiencies, and decreased overall productivity.

- Safety Risks: Non-conformance in industries like healthcare or aviation can pose significant safety risks to both employees and consumers.

Managing Non-Conformance

Effectively managing non-conformance is crucial for maintaining quality and minimizing its negative impact. Here are some key steps organizations can take:

- Identification and Reporting: Establish a clear process for identifying and reporting non-conformance issues. Encourage employees to report deviations promptly.

- Root Cause Analysis: Conduct thorough root cause analyses to understand why Its occurred. This involves identifying the underlying factors and systemic issues contributing to the problem.

- Corrective and Preventive Actions (CAPA): Develop and implement CAPA plans to address non-conformance. Corrective actions focus on resolving the immediate issue, while preventive actions aim to prevent recurrence.

- Documentation: Maintain detailed records of non-conformance incidents, investigations, and actions taken. This documentation is essential for regulatory compliance and continuous improvement.

- Training and Education: Invest in ongoing training and education for employees to prevent non-conformance related to knowledge gaps or inadequate skills.

- Quality Control: Implement robust quality control processes to catch non-conformance issues before they reach customers or impact operations.

- Supplier Management: Establish strong relationships with suppliers and monitor their performance to prevent non-conformance related to materials or components.

- Continuous Improvement: Foster a culture of continuous improvement, where non-conformance incidents are seen as opportunities for learning and growth.

Preventing Non-Conformance

While managing it is essential, preventing it in the first place is even more desirable. Here are some strategies for preventing it:

- Quality Management Systems: Implement comprehensive quality management systems (QMS) that define standards, procedures, and controls.

- Risk Assessment: Conduct regular risk assessments to identify potential areas of non-conformance and proactively address them.

- Audits and Inspections: Perform regular audits and inspections to ensure compliance with standards and regulations.

- Feedback Loops: Establish feedback mechanisms for employees to report potential issues or suggest improvements.

- Data Analytics: Utilize data analytics and monitoring tools to detect patterns or trends that may indicate non-conformance.

- Supplier Quality Assurance: Work closely with suppliers to ensure the quality and reliability of materials and components.

Conclusion

Non-conformance is a challenge that organizations across various industries must contend with. However, with proactive measures, effective management strategies, and a commitment to continuous improvement, organizations can mitigate the impact of non-conformance and strive for higher levels of quality, efficiency, and customer satisfaction. By understanding the causes, consequences, and prevention techniques related to it, organizations can move closer to their goals of excellence and success.