Mastering Measurement System Analysis: Best Practices for Quality Control Professionals

Introduction

Measurement System Analysis (MSA) is an important tool used in quality management to ensure the accuracy and reliability of a measurement system. It is a critical component of any quality control program, as correct measurements are essential for making data-driven decisions and improving processes.

MSA provides a systematic approach to evaluating the performance of measurement systems and identifying sources of variation that could affect the accuracy of the measurements.

The Importance of Measurement System Analysis

The importance of measurement system analysis is particularly clear when considering the potential implications of poorly calibrated or unreliable measurement instruments and methods.

Inaccurate or inconsistent measurements can lead to significant quality issues in the production process, resulting in wasted materials, increased costs and poor customer satisfaction.

However, by taking a proactive approach to measurement system analysis, manufacturers can help to mitigate these risks and ensure that their products meet the highest standards of quality and consistency. By identifying any potential issues with measurement instruments and methods early on, and taking steps to correct them, manufacturers can prevent quality issues before they occur, reduce waste, and often increase efficiency in the production process.

Furthermore, measurement system analysis provides a valuable tool for ongoing process improvement, helping manufacturers to identify areas of their production process that may benefit from further optimization or refinement.

Through careful analysis of measurement data, manufacturers can identify patterns or trends, and take actions to improve the accuracy and reliability of their measurement instruments and methods, ultimately leading to improved product quality, reduced waste and increased efficiency in the production process.

Components of Measurement System Analysis

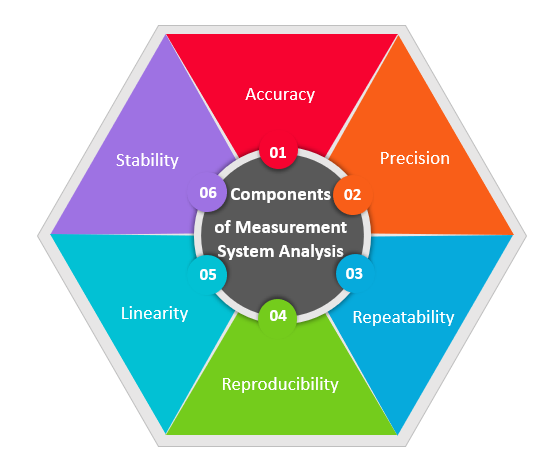

There are several components of MSA that organizations need to understand to perform it adequately. Let's dive into these components and explore how they fit together to form a comprehensive measurement system analysis.

1. Accuracy: One of the primary components of MSA is accuracy. Accuracy is the measure of how close a measured value is to the true value. In other words, the closer the measured value is to the actual value, the more accurate the measurement system is. To determine the accuracy of a measurement system, various methods can be used.

2. Precision: Precision refers to the consistency of the measurement system. It is the measure of how close the measured values are to each other. A precise measurement system produces measurements that are consistently repeatable.

3. Repeatability: Repeatability is the measure of how consistently a measurement system can produce the same result when measuring the same object multiple times. It is an important component of MSA as it helps to determine the consistency of the measurement system under repeated measures

4. Reproducibility: Reproducibility is the measure of how consistently a measurement system can produce the same result when measuring the same object but using different operators. Reproducibility assesses the ability of the measurement system to produce consistent results across different operators using the same measurement protocol.

5. Linearity: Linearity is the measure of how well the measurement system can produce measurements that are proportional to the actual values being measured. In other words, the results of the measurement should vary linearly with the actual values.

6. Stability: Stability is the measure of how the measurement system performs over time. It is an essential component of MSA as it determines whether the measurement system's performance remains consistent over time or whether it changes due to various factors such as wear and tear.

Best Practices For Maintaining a Reliable Measurement System

Some of the best practices for maintaining a reliable measurement system are as follows:

- Calibration and Verification: Calibration and verification are essential for ensuring the accuracy of a measurement system. Calibration involves comparing the measurement device against a known standard to ensure that it is reading accurately. While verification is the process of comparing the measurements taken by the measurement device to the measurements taken by another device that is traceable to a national standard.

- Proper Storage and Handling: The storage and handling of measurement devices are crucial to ensure the accuracy and reliability of the data they report. Any slight damage to the calibration system can result in inaccurate readings.

- Regular Maintenance: Regular maintenance is vital to ensure the long-term functioning of the measurement system. The frequency of maintenance depends on the device and its usage, but it should be done annually or biannually.

- Training: Proper training is vital for the proper use of the measurement devices. Employees should receive sufficient training on how to use the devices and how to take care of them. Training on calibration and verification processes should also be given so as to ensure the accuracy of the measurement devices.

- Documentation: Documentation is essential for maintaining a reliable measurement system. All calibration, verification, and maintenance results should be recorded for reference purposes. This information should be easily accessible to employees whenever needed.

Conclusion

In conclusion, measurement system analysis is an essential process in any organization that collects data. It provides an insight into the reliability and accuracy of the measurement system, and by drawing conclusions from the gathered data, the organization can determine whether the measurement system is acceptable, unacceptable, or requires improvement.