ISO 9001 Supplier Pre-Qualification Form Template

Overall, the Supplier Pre-Qualification Form ISO 9001 is a valuable tool for organizations looking to establish productive partnerships with suppliers who consistently meet their quality requirements. By implementing this form, businesses can streamline their supplier selection process, mitigate risks, and enhance the overall quality of their product offerings.

The Importance of Having a Supplier Pre-Qualification Form

When selecting suppliers for your business, ensuring they meet certain quality standards is important. One way to do this is using a supplier pre-qualification form based on the ISO 9001 standard. ISO 9001 is an internationally recognized quality management standard that sets out the criteria for a quality management system. By implementing a supplier pre-qualification form based on ISO 9001, you can ensure that your suppliers meet the necessary quality requirements and that they can consistently provide products or services that meet your expectations. This blog will explore the importance of using a supplier pre-qualification form and how it can benefit your business.

Defining Business Objectives for Supplier Pre-Qualification

Businesses must establish clear and specific business objectives when implementing a supplier pre-qualification form based on ISO 9001. These objectives serve as a guide for evaluating potential suppliers and ensuring that they align with the long-term goals and values of the company.

Here are some key business objectives that should be considered when developing a supplier pre-qualification form:

1. Quality Assurance: A primary objective for any business is to maintain and improve the quality of products or services. The pre-qualification form should include criteria to assess a supplier's commitment to quality control, quality assurance processes, and adherence to industry standards.

2. Supply Chain Efficiency: Another objective to consider is improving supply chain efficiency. This can be achieved by pre-qualifying suppliers with streamlined processes and promptly delivering products or services. The form should include questions to evaluate a supplier's production capacity, lead times, and inventory management.

3. Cost Management: Any business must control costs and maintain profitability. The pre-qualification form can include inquiries about a supplier's pricing structure, payment terms, and cost reduction initiatives. This helps ensure that the selected suppliers offer competitive pricing without compromising quality.

4. Innovation and Sustainability: In today's competitive market, businesses need suppliers who prioritize innovation and sustainability. The form should include questions to assess a supplier's commitment to research and development, sustainable practices, and compliance with environmental regulations.

5. Risk Management: Mitigating risks is a crucial objective for businesses. The pre-qualification form should include questions about a supplier's risk management strategies, contingency plans, and insurance coverage. This helps ensure the selected suppliers are prepared to handle unforeseen events that may impact the supply chain.

6. Collaboration and Communication: Effective collaboration and communication with suppliers are vital for successful partnerships. The form can include inquiries about a supplier's communication channels, responsiveness, and ability to collaborate on joint improvement initiatives.

By clearly defining these business objectives within the supplier pre-qualification form, businesses can ensure that their suppliers meet the necessary criteria to contribute to the company's success. Regularly reviewing and assessing these objectives will help maintain a high standard of supplier performance and foster long-term partnerships that drive business growth.

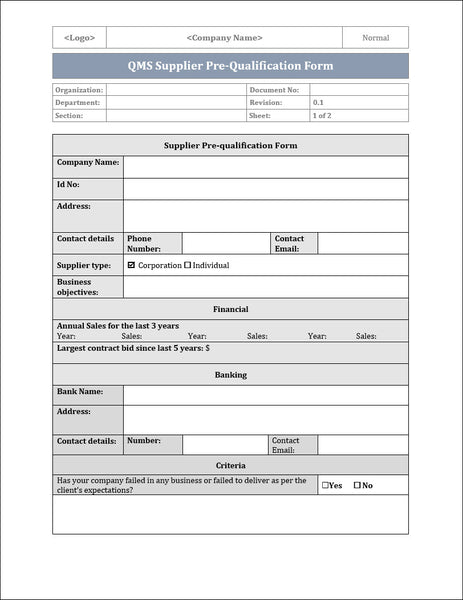

The Key Components of the Supplier Pre-Qualification Form

In the pursuit of quality management excellence, organizations often depend on their suppliers' performance and reliability. ISO 9001, the international standard for quality management systems, emphasizes the importance of a structured and meticulous supplier selection process. One essential tool in this process is the Supplier Pre-Qualification Form. This document serves as a gateway to ensuring that suppliers align with the organization's quality objectives and expectations. Let's explore the key components of this form and why they are vital for ISO 9001 compliance and overall quality assurance.

1. Company Name: At the heart of every supplier relationship is the supplier's identity. The "Company Name" field is a fundamental component of the pre-qualification form, ensuring the organization can accurately identify and record its potential suppliers.

2. Supplier Type - Corporation or Individual: Suppliers can take various forms, from large corporations to individual entrepreneurs. This section of the form clarifies the supplier's legal structure, helping the organization understand the nature of the entity they are considering for partnership.

3. Business Objectives: Understanding the supplier's business objectives is crucial. By delineating their goals, the organization can assess whether the supplier's mission and values align with theirs. This alignment is pivotal for a successful and long-lasting supplier relationship.

4. Financial Information - Annual Sales and Largest Contract Bid: Financial stability is a critical consideration in supplier selection. Information regarding annual sales and the size of the most significant contract bid gives insight into the supplier's financial health and capacity. It helps determine whether the supplier can meet the organization's demands without financial strain.

5. Banking: This section gathers data on the supplier's banking relationships and financial institutions. It can verify the supplier's financial standing and gauge their ability to handle transactions efficiently and securely.

6. Criteria: The "Criteria" section is where the organization lays out its specific requirements and expectations for suppliers. These criteria could encompass quality standards, performance metrics, regulatory compliance, etc. It is a pivotal part of the form, providing clear guidance to potential suppliers regarding the organization's expectations.

7. References: Gathering references from past or current customers is a valuable practice in supplier pre-qualification. These references offer insights into the supplier's past performance, reliability, and ability to meet expectations. It provides a valuable opportunity for the organization to learn from other's experiences and make informed decisions.

In conclusion, the Supplier Pre-Qualification Form within ISO 9001 is a powerful tool that enables organizations to establish and maintain high-quality supplier relationships. Each component plays a crucial role in evaluating potential suppliers, ensuring they align with the organization's objectives, values, and quality standards. By diligently utilizing this form, organizations can meet ISO 9001 compliance requirements and enhance their supply chain efficiency, reduce risks, and foster relationships with suppliers committed to excellence.

Conclusion

In conclusion, incorporating proper references into your writing is crucial for several reasons. Firstly, references enhance the credibility of your work by showing that reputable sources support it. This helps readers trust the information and consider it reliable. Secondly, references ensure the accuracy of your writing by providing evidence to support your claims and arguments. You back up your ideas by citing specific sources and adding depth and validity to your work.