ISO 45001 Nonconformity and Corrective Action Procedure Template

Introduction

ISO 45001 sets the standard for occupational health and safety management systems, ensuring that organizations provide a safe and healthy workplace for their employees. Nonconformity and corrective action procedures are critical components of maintaining compliance with ISO 45001 requirements.

Understanding how to identify nonconformities, implement corrective actions, and prevent recurrence is essential for organizations looking to achieve and maintain certification. This blog will provide an introduction to the ISO 45001 nonconformity and corrective action procedure, outlining the key steps and best practices for successful implementation.

Identifying Non-Conformities in your Organization

One key aspect of ISO 45001 is the identification of nonconformities within your organization. Nonconformities refer to any situation where your organization's processes, products, or services do not meet the requirements set out in the standard.

To effectively identify nonconformities, organizations should establish a systematic process for monitoring, measuring, and evaluating their performance against the requirements of ISO 45001. This can include conducting regular audits, inspections, and reviews of processes, procedures, and documentation.

When a nonconformity is identified, it is important to take immediate action to address the issue and prevent its recurrence. This may involve implementing corrective actions to eliminate the root cause of the nonconformity, as well as preventive actions to prevent similar issues from arising in the future.

By proactively identifying and addressing nonconformities, organizations can improve their overall performance and enhance their ability to achieve their health and safety objectives. This can help to create a safer and healthier work environment for employees, reduce the risk of accidents and incidents, and demonstrate a commitment to continual improvement in occupational health and safety management.

Corrective actions are essential in maintaining a safe and healthy work environment in accordance with ISO 45001 requirements. Implementing corrective actions effectively requires a systematic approach to address hazards, risks, and non-conformities identified during the workplace health and safety management process.

Implementing Corrective Actions Effectively

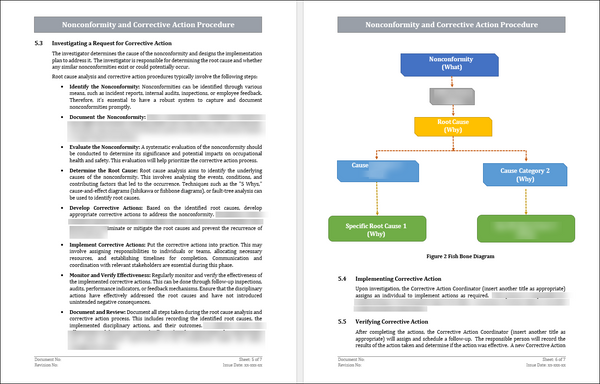

Here are some steps to effectively implement corrective actions in accordance with ISO 45001:- Identify the Root Cause of the Issue: Conduct a comprehensive investigation to determine the underlying cause of the problem. This may involve reviewing incident reports, conducting interviews, or conducting a workplace inspection.

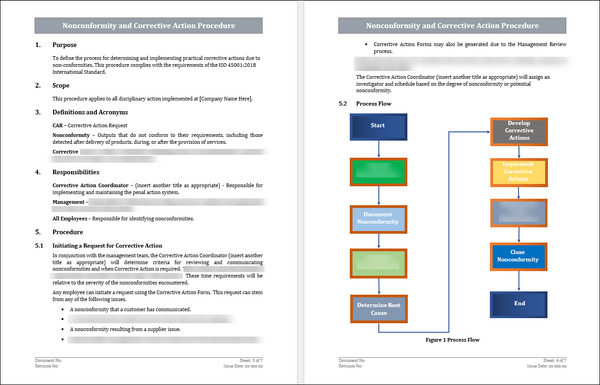

- Develop an Action Plan: Create a detailed plan outlining the steps that need to be taken to address the issue. This plan should include specific tasks, deadlines, and responsibilities for each team member involved in the corrective action process.

- Implement the Corrective Actions: Execute the action plan by assigning tasks to respective team members and monitoring progress closely. Ensure that all actions are completed according to the specified timeline.

- Monitor and Evaluate Effectiveness: Regularly assess the effectiveness of the corrective actions to ensure that the issue has been successfully resolved. This may involve conducting follow-up inspections, reviewing incident reports, or gathering feedback from employees.

- Document and Communicate Outcomes: Keep detailed records of all corrective actions taken, including any changes made to policies, procedures, or training programs. Communicate the outcomes of the corrective actions to employees to demonstrate the organization's commitment to health and safety.

By following these steps, organizations can effectively implement corrective actions to ensure compliance with ISO 45001 requirements and promote a safe and healthy work environment for all employees.

Monitoring and Reviewing Corrective Actions

Monitoring and reviewing corrective actions is an essential component of an effective occupational health and safety management system. ISO 45001 outlines specific requirements for monitoring and reviewing corrective actions to ensure continuous improvement in workplace safety.- Establish a System for Monitoring Corrective Actions: Develop a clear process for monitoring and tracking corrective actions to ensure they are completed in a timely manner. Assign responsibilities, set deadlines, and establish communication channels for reporting progress.

- Conduct Regular Reviews: Schedule regular reviews to evaluate the effectiveness of corrective actions and determine if any additional measures are needed. Assess whether the root causes of incidents have been addressed and verify that the desired outcomes have been achieved.

- Document Results and Lessons Learned: Document the results of monitoring and reviewing corrective actions, including any successes, failures, or ongoing challenges. Use this information to identify trends, lessons learned, and opportunities for improvement.

- Communicate Findings: Share the results of monitoring and reviewing corrective actions with relevant stakeholders, including employees, management, and external partners. Keep all parties informed of progress and solicit feedback for further improvement.

- Implement Corrective Actions as Needed: If monitoring and reviewing identify gaps or deficiencies, take action to address them promptly. Adjust processes, provide additional resources, or conduct further investigations as necessary to prevent recurrence of incidents.

By following these steps, organizations can ensure that corrective actions are effectively monitored and reviewed to maintain a safe and healthy work environment in accordance with ISO 45001 requirements.

Conclusion

Effective implementation of ISO 45001 standards is crucial for ensuring a safe and healthy work environment for all employees. Nonconformity and corrective action procedures play a key role in maintaining compliance with these standards.

By identifying areas of nonconformity, implementing corrective actions, and monitoring progress, organizations can continuously improve their occupational health and safety management systems. In conclusion, a robust nonconformity and corrective action procedure is essential for achieving and maintaining ISO 45001 certification.