ISO 45001 Non-Conformance Form Template

Introduction

ISO 45001 is an international standard that sets requirements for occupational health and safety management systems. In today's fast-paced and competitive business environment, organizations must prioritize the safety and well-being of their employees. One important aspect of maintaining compliance with ISO 45001 standards is effectively addressing non-conformances.

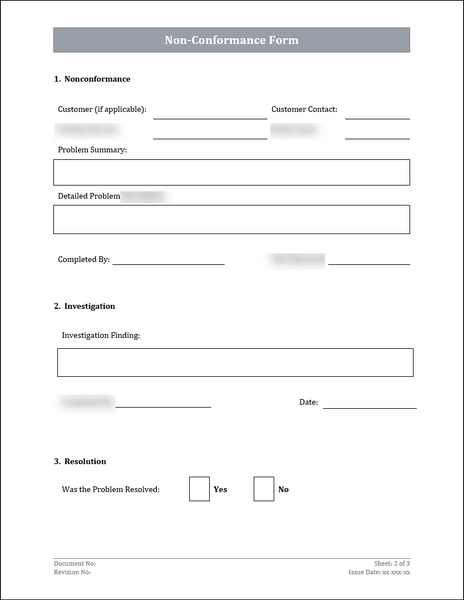

Non-conformance forms play a crucial role in documenting deviations from established procedures and identifying corrective actions to prevent future incidents. This blog will provide an in-depth introduction to ISO 45001 non-conformance forms, their importance, and best practices for implementing them in your organization.

Documenting non-conformances is a critical aspect of any occupational health and safety management system, as it helps to ensure that potential risks and hazards are properly identified, addressed, and corrected in a timely manner. By documenting non-conformances in a systematic and detailed manner, organizations can effectively track and monitor issues, analyze root causes, and implement corrective actions to prevent recurrence.

Importance of Documenting Non-Conformances

Some of the key reasons why documenting non-conformances is important include:

- Accountability and Transparency: By documenting non-conformances, organizations can establish a clear record of events, actions taken, and individuals responsible for addressing issues. This helps to hold employees, managers, and other stakeholders accountable for their actions and decisions related to health and safety.

- Continuous Improvement: Documenting non-conformances provides valuable data that can be used to identify trends, patterns, and recurring issues within the organization. By analyzing this information, organizations can implement corrective and preventive actions to improve their processes, systems, and overall safety performance.

- Compliance and Legal Requirements: Keeping a record of non-conformances is essential for demonstrating compliance with relevant health and safety regulations, standards, and requirements. Documentation can serve as evidence of due diligence and can help organizations avoid potential legal liabilities and penalties.

- Communication and Awareness: Documenting non-conformances ensures that relevant information is effectively communicated within the organization. By sharing details of incidents, near misses, and other non-conforming events, organizations can raise awareness, promote safety culture, and encourage employees to report hazards and concerns.

- Performance Monitoring and Reporting: Documenting non-conformances allows organizations to track their performance, measure the effectiveness of their safety management system, and report on key health and safety indicators. This information can be used to evaluate the success of safety initiatives, set targets for improvement, and benchmark against industry best practices.

Documenting non-conformances is an essential part of maintaining a safe and healthy work environment. By recording and analyzing incidents, deviations, and other issues, organizations can proactively identify and address risks, prevent accidents and injuries, and promote a culture of continuous improvement in occupational health and safety.

Ensuring Compliance with ISO 45001 Standards

- One of the key components of ensuring compliance with ISO 45001 standards is the use of a non-conformance form. A non-conformance form is a document that records any instances where an organization fails to meet the requirements of ISO 45001. This form is an essential tool for identifying and addressing issues that may arise during the implementation of the standard.

- When filling out a non-conformance form, it is important to provide detailed information about the issue at hand. This includes documenting the date and time of the non-conformance, the nature of the non-conformance, and any potential risks or hazards that may result from it. By providing this information, organizations can take the necessary steps to rectify the issue and prevent it from happening again in the future.

- In addition to documenting non-conformances, organizations should also conduct regular audits to ensure compliance with ISO 45001 standards. Audits help to identify any gaps or deficiencies in the occupational health and safety management system, allowing organizations to take corrective action before any serious incidents occur.

- Overall, ensuring compliance with ISO 45001 standards is crucial for the success and sustainability of any organization. By using tools such as non-conformance forms and conducting regular audits, organizations can demonstrate their commitment to providing a safe and healthy work environment for their employees.

- Compliance with ISO 45001 not only benefits employees but also helps organizations reduce the risk of costly accidents and legal issues. In today's world, where occupational health and safety are of utmost importance, organizations that prioritize compliance with ISO 45001 standards will undoubtedly gain a competitive edge in the market.

Implementing Corrective Actions to Prevent Future Non-Conformance

ISO 45001 is an international standard for occupational health and safety management systems. It provides a framework for organizations to identify, control, and continually improve their health and safety performance. One key aspect of ISO 45001 is addressing non-conformances, which are instances where an organization's practices do not meet the standard's requirements.

- Implementing corrective actions to prevent future non-conformances is crucial for maintaining a safe and healthy work environment for employees. It involves identifying the root cause of the non-conformance, developing a plan to address it, and implementing measures to prevent it from happening again.

- One effective way to implement corrective actions is to use a structured approach, such as the Plan-Do-Check-Act (PDCA) cycle. This method involves planning the corrective action, implementing it, checking its effectiveness, and adjusting the plan as needed to prevent future non-conformances.

- Another important aspect of implementing corrective actions is communication. It is essential to communicate the corrective action plan to all relevant stakeholders, including employees, management, and any external parties involved. This ensures that everyone is aware of the steps being taken to address the non-conformance and prevent it from happening again.

- Additionally, monitoring and reviewing the effectiveness of the corrective actions is key to preventing future non-conformances. This involves tracking progress, measuring results, and making adjustments as needed to ensure that the corrective actions are achieving the desired outcomes.

Implementing corrective actions to prevent future non-conformances is essential for maintaining a safe and healthy work environment in accordance with ISO 45001. By using a structured approach, communicating effectively, and monitoring and reviewing the effectiveness of the corrective actions, organizations can prevent non-conformances and improve their health and safety performance.

Conclusion

The ISO 45001 standard is a critical tool for organizations looking to improve their occupational health and safety management systems. One key aspect of implementing ISO 45001 is the handling of non-conformances, which are instances where the organization fails to meet the requirements of the standard.

Having a robust non-conformance form is essential for documenting, investigating, and resolving these issues in a timely and effective manner. This article will provide a comprehensive conclusion on ISO 45001 non-conformance forms, including their importance, key elements, and best practices for addressing non-conformances to ensure ongoing compliance with the standard.