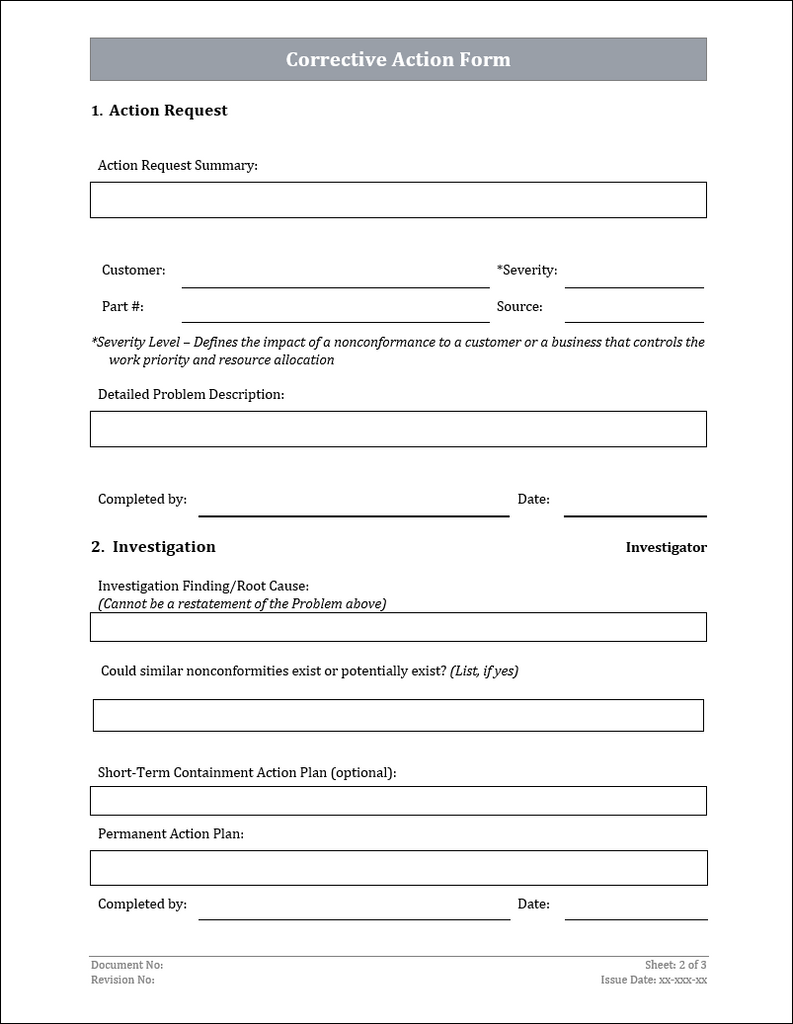

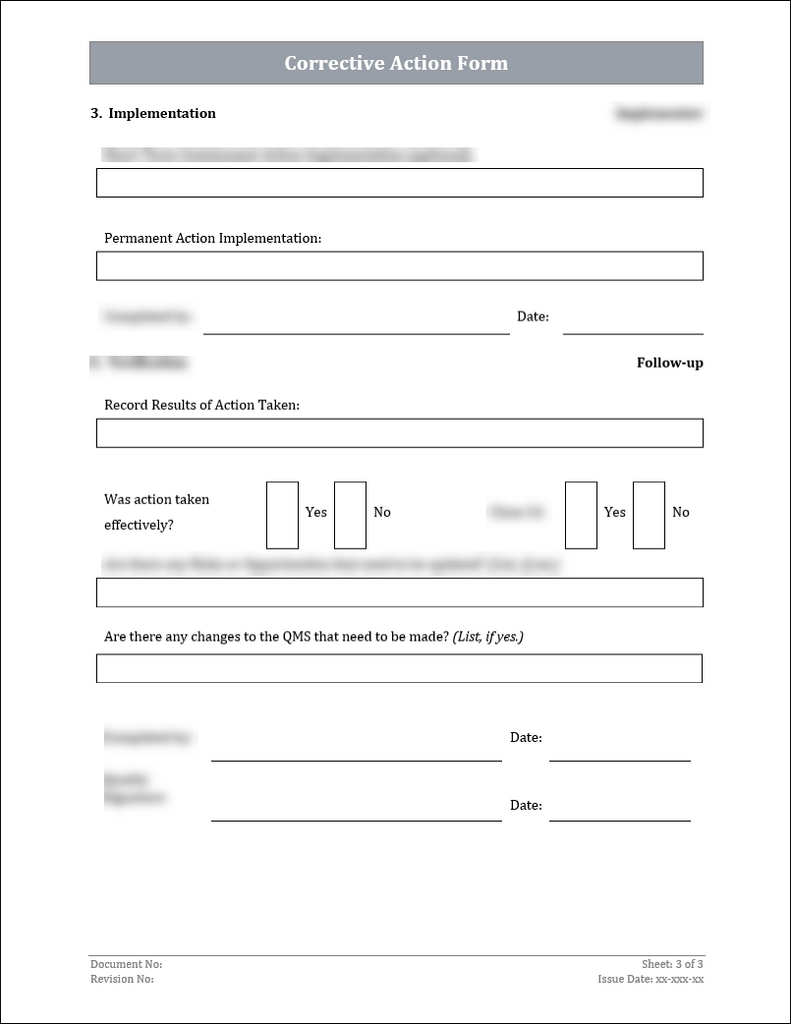

ISO 45001 Corrective Action Form Template

Introduction

Maintaining compliance with ISO 45001 standards is crucial for organizations regarding workplace safety and health. A critical aspect of this compliance is the implementation of corrective action procedures to address any nonconformities and prevent potential hazards. A well-designed Corrective Action Form for the ISO 45001 Template ensures a systematic and practical approach to corrective actions. This template provides a structured format for documenting corrective actions, assigning responsibilities, setting deadlines, and tracking implementation progress. In this blog post, we will delve into the critical components of this template and how it can help your organization maintain a safe and healthy work environment.

Significance Of Implementing Corrective Actions In ISO 45001

Corrective actions play a significant role in the ISO 45001 standard as they help organizations address nonconformities and improve their occupational health and safety management system. By implementing corrective actions, organizations can:

1. Address Root Causes: Corrective actions help organizations identify and address the underlying causes of nonconformities rather than just treating the symptoms. This helps prevent the recurrence of the same issues in the future.

2. Ensure Compliance: By implementing corrective actions, organizations can ensure that they comply with legal and other occupational health and safety requirements. This helps avoid potential fines or legal issues.

3. Improve Performance: Corrective actions allow organizations to improve their occupational health and safety performance by identifying areas for improvement and taking steps to address them.

4. Enhance Reputation: By demonstrating a commitment to addressing nonconformities and continuously improving their health and safety management system, organizations can enhance their reputation with stakeholders, including employees, customers, and regulators.

5. Increase Efficiency: Corrective actions can help organizations identify inefficiencies in their processes and procedures, increasing efficiency and productivity.

Monitoring And Reviewing Corrective Actions For Continuous Improvement

Monitoring and reviewing corrective actions are essential to continuous improvement. Here are some critical steps to ensure effective monitoring and review:

1. Set Clear Objectives: Clearly define the goals and objectives of the corrective actions to improve skills. This will help guide the monitoring and review process.

2. Establish Metrics: Define key performance indicators (KPIs) to measure the effectiveness of the corrective actions. These could include improvements in grammar, vocabulary, pronunciation, or overall language proficiency.

3. Regularly Track Progress: Monitor the implementation of corrective actions regularly to ensure they are effectively carried out. This could include conducting regular assessments or evaluations of language skills.

4. Collect Feedback: Gather feedback from individuals who are implementing the corrective actions and those who are receiving the training. This will help identify any areas for improvement and ensure that the corrective actions have the desired impact.

5. Review Results: Analyze the results of the corrective actions to determine their effectiveness. This could involve comparing current language skills to baseline measurements taken before the corrective actions were implemented.

6. Make Adjustments: Based on the monitoring and review process results, adjust the corrective actions as needed. This could involve revising training materials, providing additional support, or implementing new strategies.

Best Practices For Effective Corrective Action Implementation

1. Establish Clear Objectives And Goals: Before implementing corrective actions, clearly outline the objectives and goals you want to achieve. This will help guide the entire process and ensure everyone works towards the same end goal.

2. Identify Root Causes: Take the time to properly investigate and analyze the root causes of the issues that led to the need for corrective action. Identifying the underlying reasons for the problem will help you develop a more effective solution.

3. Develop A Detailed Action Plan: Once you have identified the root causes, develop a detailed action plan that outlines the steps you need to take to address the issue. Include specific tasks, timelines, responsible parties, and resources needed for each action.

4. Communicate Effectively: Clear communication is essential when implementing corrective actions. Communicate the action plan with all relevant stakeholders, provide updates on progress, and address any concerns or questions.

5. Monitor Progress: Regularly monitor the progress of the corrective actions to ensure that they are implemented effectively and have the desired impact. Adjust the action plan as needed based on your feedback and results.

6. Document All Actions Taken: Keep detailed records of all actions taken while implementing corrective actions. This documentation will be necessary for monitoring progress, evaluating effectiveness, and demonstrating compliance with regulations or standards.

7. Evaluate Effectiveness: Once the corrective actions have been fully implemented, evaluate their effectiveness in addressing the initial problem. Determine if the desired results have been achieved and if further actions are needed.

8. Continuous Improvement: Use the experience from implementing corrective actions to improve your processes, systems, and practices continuously. Incorporate lessons learned into future actions to prevent similar issues from occurring.

Conclusion

In summary, utilizing a Corrective Action Form for ISO 45001 is crucial in maintaining a safe and compliant work environment. This template provides a structured approach to addressing non-conformities and improving your organization's occupational health and safety practices. By implementing this form, you can ensure that corrective actions are properly documented, tracked, and resolved per ISO 45001 standards. Download our template today to streamline your corrective action processes and enhance your safety management system.