7.1.4 Environment For The Operation Of Processes

Environment For The Operation Of Processes

An organisation needs to establish, implement, and maintain an environment for the operation of processes. The environment for the operation of processes is a condition that affects and is necessary for the operation of the process.

The environment for the operation of processes includes the physical, organisational, and technical resources, as well as the conditions under which the process is carried out.

The environment for the operation of processes is a condition that can be controlled by the organisation and that can affect the process. The environment for the operation of processes must be suitable for the intended purpose of the process.

The environment for the operation of processes must be controlled to ensure the process outputs meet the requirements. The environment for the operation of processes includes the physical, organisational, and technical resources, as well as the conditions under which the process is carried out.

To ensure effective and efficient operation of processes, ISO 9001:2015 requires organisations to establish and maintain an appropriate environment. The standard defines the environment for the operation of processes as the combination of all factors that affect processes and their results.

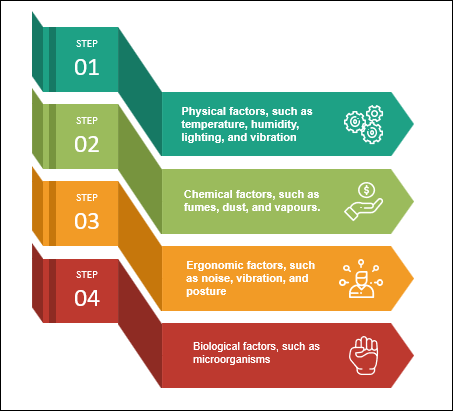

The environment for the operation of processes includes, but is not limited to, the following:

- Physical factors, such as temperature, humidity, lighting, and vibration.

- Chemical factors, such as fumes, dust, and vapours.

- Ergonomic factors, such as noise, vibration, and posture.

- Biological factors, such as microorganisms.

ISO 9001:2015 requires organisations to determine the effects of the environment on the operation of processes, and to take appropriate actions to minimise those effects. To do this, organisations need to have a clear understanding of their processes and the factors that affect them.

The environment for the operation of processes must be reviewed and, if necessary, updated as the process is carried out, to ensure the process outputs meet the requirements.

The environment for the operation of processes must be monitored and controlled to ensure the process outputs meet the requirements. The environment for the operation of processes must be monitored and improved to enhance process effectiveness.

Definition and Determination of Process Environment

To ensure that the process environment is conducive to the quality of the product or service being provided, it is necessary to define and determine the process environment. The process environment is the set of all factors and conditions that could reasonably be expected to affect the process.

To ensure that the process environment is conducive to the quality of the product or service being provided, it is necessary to define and determine the process environment. The process environment is the set of all factors and conditions that could reasonably be expected to affect the process.

The process environment must be taken into account when designing, implementing, and maintaining a process. It is also necessary to consider the environment when assessing the risks and opportunities associated with the process.

There are a number of factors that need to be considered when defining and determining the process environment. These include the following:

- The type of product or service being provided

- The intended use of the product or service

- The customer’s requirements

- The regulatory requirements

- The geographical location

- The climate

- The availability of resources

- The type of equipment being used

- The work environment.

Difference between the Process Environment and Infrastructure?

ISO 9001 is a quality management system (QMS) standard that provides guidance and requirements for organisations wishing to improve their quality management system.

One of the key requirements of the standard is the need for organisations to establish a documented quality management system. Part of this documentation includes a description of the process’s environment, which is also known as the process infrastructure.

The process environment includes all the factors that affect and influence the operation of the process. This includes the people, equipment, materials, methods, and facilities that are used in the process.

In contrast, the infrastructure refers to the systems, methods, and procedures that support the process environment. This includes the quality management system itself, as well as the policies, procedures, and resources that are used to manage the process environment.

So, what’s the difference between these two concepts? And why is it important to understand the difference?

The key difference between the process environment and the infrastructure is that the process environment includes all the factors that affect and influence the operation of the process, while the infrastructure refers to the systems, methods, and procedures that support the process environment.

It’s important to understand the difference between these two concepts because they have a direct impact on the quality of the product or service being produced. The process environment includes all of the elements that can directly affect the outcome of the process, so it’s important to control these elements as much as possible.

The infrastructure provides the framework for how the process environment is managed, so it’s important to ensure that this framework is effective in supporting the quality management system.

Review and Evaluation of Risks Related to the Process Environment

Risk management is the process of identifying, assessing, and controlling risks to an organisation. It is an important part of any business or manufacturing process, as it helps to ensure the safety of both employees and customers.

There are several different risks that can be associated with the process environment. These risks can be related to the physical environment, the chemical environment, or the human environment.

It is important to identify and assess these risks to control them. This can be done through a process of review and evaluation. By understanding the risks, you can develop a plan to control them. The first step in the risk management process is to identify the risks.

This can be done by looking at the process environment and identifying potential hazards. Once these hazards have been identified, they can be assessed in terms of their likelihood and consequences.

Once the risks have been identified and assessed, they can then be controlled.

There are several different ways to control risks. These include eliminating the hazard, substituting a less hazardous material, introducing engineering controls, or implementing administrative controls.

The goal of risk management is to reduce or eliminate the adverse effects of risks on an organisation. By identifying and assessing risks, you can develop a plan to control them and protect your employees and customers.