ISO 9001 Equipment Calibration Form Template

The ISO 9001 Equipment Calibration Form Template is a document designed to assist organizations in maintaining accurate and reliable calibration records for their equipment. Calibration is the process of checking and adjusting a piece of equipment to ensure its accuracy and reliability. This form template provides a structured format for recording important details such as equipment identification, calibration date, calibration results, and any necessary adjustments or repairs made during the calibration process. By using this template, organizations can ensure that their equipment is properly calibrated, meet industry standards, and comply with the requirements of ISO 9001 quality management system certification.

Purpose of an ISO 9001 Equipment Calibration Form

- Documentation: An ISO 9001 Equipment Calibration Form is used as a documented record to keep track of equipment calibration activities. It ensures that all calibration activities are properly documented, including the date of calibration, equipment identification, and any adjustments made during the process.

- Compliance: ISO 9001 is an international standard for quality management systems, and it requires organizations to have a systematic approach to equipment calibration. By using the Equipment Calibration Form, organizations can demonstrate compliance with this requirement and provide evidence of their commitment to quality management practices.

- Traceability: The form helps establish traceability by recording the calibration reference standards used in the process. This ensures that the calibration is based on reliable and traceable references, reducing the risk of inaccurate or unreliable measurements.

- Preventive Maintenance: The Equipment Calibration Form can also serve as a preventive maintenance tool by providing a clear schedule for equipment calibration. It helps organizations track when equipment needs to be calibrated, ensuring timely calibration to prevent any potential issues or deviations.

- Risk Management: Calibration is critical for maintaining the accuracy and reliability of equipment. Using the form, organizations can identify any potential risks associated with the equipment calibration process. By regularly reviewing and updating the form, organizations can minimize the risk of equipment failure and mitigate the impact on product quality and customer satisfaction.

- Continuous Improvement: The Equipment Calibration Form also supports organizations' continuous improvement efforts. By documenting the calibration results, organizations can analyze data trends over time to identify opportunities for process improvements. This can lead to better equipment performance, increased operational efficiency, and enhanced product quality.

- Audits and Inspections: During audits and inspections, organizations are required to demonstrate that they have effective calibration processes in place. The Equipment Calibration Form provides the necessary documentation to show that equipment is regularly calibrated in accordance with the established procedures, helping organizations pass audits and inspections more smoothly.

In summary, the purpose of an ISO 9001 Equipment Calibration Form is to ensure proper documentation, compliance with standards, traceability, preventive maintenance, risk management, continuous improvement, and support for audits and inspections. It helps organizations maintain accurate and reliable equipment, enhance product quality, and demonstrate their commitment to implementing effective quality management practices.

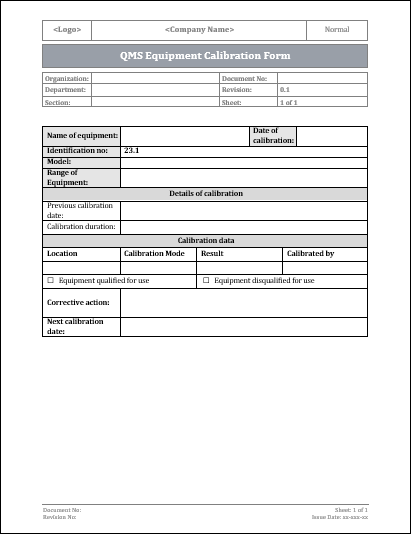

Key Elements To Include In Your Equipment Calibration Form

- Date of Calibration: This refers to the specific date on which the equipment was calibrated. It is important to record this information accurately for future reference and tracking purposes.

- Range of Equipment: This indicates the range or capacity of the equipment that was calibrated. It helps to determine the accuracy and reliability of the equipment within a specific range.

- Calibration Duration: This refers to the time taken to calibrate the equipment. It helps to determine the efficiency of the calibration process and ensures that the equipment is properly adjusted for accurate measurements.

- Calibration mode: This specifies the method or mode used for calibration, such as manual or automated calibration. It ensures that the equipment is calibrated using the appropriate method to obtain accurate results.

- Corrective Action: This refers to any corrective measures taken during the calibration process. If any issues or discrepancies are identified during calibration, corrective action helps to rectify the problem and ensure that the equipment meets the necessary standards.

Overall, these key elements of the ISO 9001 Equipment Calibration Form template help to document and track the calibration process, ensuring that equipment is regularly calibrated and maintained in accordance with quality standards.

Benefits of Using an ISO 9001 Equipment Calibration Form Template Plan

Using an ISO 9001 equipment calibration form template plan offers several benefits:

- Compliance with ISO 9001 requirements: ISO 9001 is an international standard for quality management systems. By using a template that aligns with ISO 9001 requirements, organizations can ensure that their calibration processes are in compliance with the standard.

- Time and cost savings: Creating a calibration form plan from scratch can be time-consuming and expensive. By using a pre-designed template, organizations can save time and resources in developing a calibration plan.

- Improved documentation: The template provides a structured format for documenting calibration activities, including equipment identification, calibration procedures, calibration results, and any deviations or corrective actions taken. This documentation helps to maintain accurate records of calibration activities, which is essential for quality control and audit purposes.

- Enhanced traceability: The template can include fields for recording calibration standards used, calibration dates, and the names of personnel responsible for performing the calibration. This information helps to establish a clear audit trail and traceability of calibration activities.

- Increased efficiency: A well-designed calibration form template plan can streamline the calibration process, making it more efficient and reducing the chances of errors or omissions. This can save time and effort for calibration technicians and improve overall productivity.

- Continual improvement: ISO 9001 emphasizes the importance of continual improvement in quality management systems. By using an ISO 9001 equipment calibration form template plan, organizations can easily identify areas for improvement and implement corrective actions to enhance their calibration processes over time.

Overall, using an ISO 9001 equipment calibration form template plan can help organizations to establish a robust and standardized calibration process, ensuring the accuracy and reliability of their equipment and facilitating compliance with ISO 9001 requirements.

Conclusion

Overall, the ISO 9001 Equipment Calibration Form is a necessary tool for maintaining the quality and accuracy of equipment in an organization. By implementing this form, organizations can ensure that their equipment is regularly calibrated, reducing the risk of errors and improving overall performance. The form also provides a systematic approach to documenting calibration activities, which can be helpful for audits and regulatory compliance. Ultimately, the ISO 9001 Equipment Calibration Form is an essential component of any quality management system.