Emergency Response Procedure Template

In an emergency, businesses must have a plan in place to ensure the safety of employees, customers, and the general public. An Emergency Response Procedure (ERP) is a plan that outlines the steps to be taken in an emergency. The ISO 14001 standard requires businesses to have an ERP in place to be certified.

The standard outlines the minimum requirements for an ERP, including the roles and responsibilities of employees, the communication plan, and the steps to be taken in an emergency. An effective Emergency response procedure can mean the difference between a minor incident and a major disaster.

How To Develop An Emergency Response Procedure For Your Business?

An effective ERP can mean the difference between a minor incident and a major disaster. This blog will look at the requirements of the ISO 14001 standard and how you can develop an effective ERP for your business.

- The first step in creating an ERP is identifying the hazards that could affect your business. This includes both external and internal threats. External risks are beyond your control, such as severe weather events. Internal stakes are those you control, such as a chemical spill. Once you have identified the dangers, you need to assess the risks associated with each bet. This will help you to determine the steps that need to be taken to mitigate the risks.

- The next step is to develop the emergency response plan itself. The program should be designed to protect employees, customers, and the general public from harm. It should also be prepared to minimize damage to property and the environment. The plan should be written clearly and concisely so that it can be quickly followed in an emergency.

- Once the plan has been developed, it is essential to train all employees on the procedures outlined in the program. Employees should know how to evacuate the premises safely and contact emergency services if necessary. They should also be familiar with the steps that need to be taken to prevent the spread of contamination.

How To Implement The ISO 14001 Emergency Response Procedure?

While the steps outlined in ISO 14001 are not mandatory, they can be very helpful in ensuring that your emergency response plan is up to par. This blog post will discuss implementing your organization's ISO 14001 emergency response procedure.

- Establish an emergency response team- The first step in ISO 14001 emergency response is to establish an emergency response team. This team should be responsible for coordinating the emergency response and ensuring that everyone is safe. The team should also have a plan for dealing with the aftermath of the emergency.

- Notify relevant parties- Once the emergency response team has been established, it is essential to notify appropriate parties of the situation. This includes people who may be affected by the emergency, such as employees, customers, and suppliers. It is also important to notify local authorities, such as the police or fire department.

- Activate the emergency response plan- The next step is to activate the emergency response plan. This plan should outline how to deal with the emergency and its aftermath. It should also include grades for evacuating people from the area and providing medical assistance. Once the plan has been activated, it is essential to follow it closely to ensure everyone's safety.

Instructions To Use The Template

All yellow indicated numbers need action to be taken. Below are details

1. Provide the Revision History of the document

- Revision Number: in the order of 00,01,02, etc.

- Date: Revision Date of Document in dd-mmm-yyyy.

- Prepared By: Name of the person who prepared the document

- Reviewed By: Name of the person who reviewed the document after revision

- Approved By: Name of the person who approved the document after revision

- Description: Provide the description of the revision

2. Insert Company Name

3. Modify Emergency Scenario as per specific organization and location

4. Modify as per organization

5. Any other Fire Preventive and Detection Measures

6. Add Response to different Emergency Scenarios

7. Add or Modify training modules

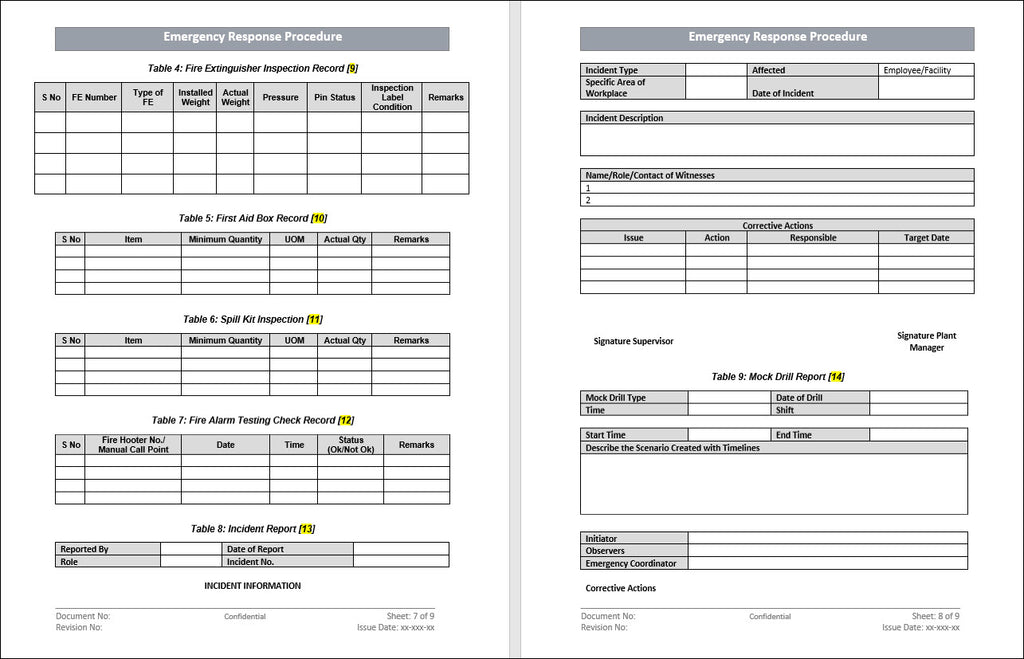

8. Add more inspection records as per the organization

9. Fire Extinguisher Inspection Record

FE Number – Any numbering that is fixed on FE, such as

- FE-1, 2, etc.

- Type of FE – CO2, Foam, DCP, etc.

- Installed Weight – Weight of FE Cylinder as per manufacturing

- Actual Weight – Incase of CO2 cylinders, measure the weight

- Pressure – In case of any other cylinder apart from CO2, a pressure gauge is installed. Mention whether ok or not ok as per the arrow in the safe zone

- Pin Status – If any Pin is installed to unhook the mouth of the Fire Extinguisher, mention such as In Place/Broken as per actual

- Inspection Label Status – Provide whether the inspection label paste on the cylinder is legible

- Remarks – If there are any additional comments.

- Item – Mention the things to be available as per local/country laws, such as Band-Aid, Dettol, etc.

- Minimum Quantity – Provide the minimum quantity against the items

- UOM – Units of measurement

- Actual Quantity – Quantity at the time of inspection

- Remarks – Any remarks

11. Spill Kit Inspection

- Item – Mention the things to be available as per local/country laws, such as Spill Bundle, Dust Picker, Gloves, etc.

- Minimum Quantity – Provide the minimum quantity against the items

- UOM – Units of measurement

- Actual Quantity – Quantity at the time of inspection

- Remarks – Any remarks

- 12 - Fire Alarm Testing Check Record

- Fire Hooter No./ MCP no. – Provide the label provided, such as MCP 1, Hooter 1, etc.

- Date – Date of testing

- Time – Time of testing

- Status – Ok/Not Ok

- Remarks – If any

13. Incident report – Fill in the details as required in the form or modify them as per the requirement

14. Mock Drill Report - Fill in the details as required in the form or modify them as per the requirement